Yooqi Emulsion maintenance system is a revolutionary innovation for aluminum hot-rolling coolant quality control. When you use this system to maintain your emulsion, your emulsion quality and your product quality will have amazing changes.

The emulsion is a mixture, This dispersive mixture has properties such as flocculation, coalescence, Ostwald ripening, creaming, chemical reaction, etc. These properties make the emulsion form a distinct layer of oil and water when not strongly stirred. When we independently studied the water and lubricating oil in the aluminum hot rolling emulsion, It is easy to accurately find the problem of affecting the cleanliness of the emulsion. Is the water dissolved too much salt or is there a problem with the lubricant?

In order to remove insoluble pollutants in the emulsion, the traditional purification method relies only on filtration. Filtration removes only about 10 microns of insoluble contaminants. The tiny insoluble contaminants can only be cleaned by partial dumping.

Recent research has shown that the production of tramp oil is the ability of the emulsion to cleaning itself. The tramp oil has adhesion and floating properties, and it has the same purification function as the flotation agent. The flotation purification technology is the most reliable way into remove tiny soluble contaminants. When the flotation agent is mix with the insoluble contaminants, it will coalesce into surface tramp oil or suspended tramp . the ash contaminants of the emulsion can be coalesced in the trump oil, The darker the color of the tramp oil , the more ash contaminants is coalesced, As long as we make full use of the tramp oil , Timely removal of the tramp oil from the emulsion ,we can effectively maintain the cleanliness of the emulsion in an optimal range, And reduce or even eliminate the partial dumping caused by the removal of tiny insoluble contaminants

Dissolved salts in water can be measured by conductivity, An increase in conductivity indicates an increase in the dissolved salt of water .

It is not possible to remove salts dissolved in water using existing techniques without disturbing the composition of the emulsion, Therefore, The partial dumping is required only when the conductivity of the water rises to an intolerable level.

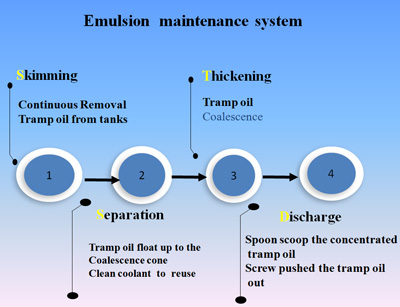

YooQi emulsion maintenance system makes full use of the tramp oil cleaning ability of the emulsion. The world's first separation method is applied to the aluminum hot-rolling emulsion system, It completely separate and remove the insoluble contaminants in the emulsion.

This system is continuously online skimming, separation, concentration, etc. The tramp oil that coalesces largest amount insoluble contaminants is discharged from the emulsion system in the form of concentrated tramp oil . This type of bypass treatment achieves the goal of no downtime maintenance. The amount of bypass treatment is very few compared to the emulsion working. It does not affect the matching of the original system pump, and minimizing heat loss.

BENEFITS

•• Improve product quality

•• Eliminate equipment downtime

•• Reduce coolant dumps

•• Reduce operating costs

•• Improve process performance

•• No noise

•• Minimum energy consumption

•• No filter media

•• Easy to use

•• High reliability